- Top page

- Product Information

- FDM method desktop 3D printer MF series

FDM method desktop 3D printer MF series

For jigs and tools! For samples!

Reliable made in Japan, full support with Japanese language,

FDM method desktop 3D printer MF series

![]()

Jigs and tools used for assembly are so expensive, even though you don’t use that many, aren’t it? A 3D printer can save you money in a short period of time.

For companies that handle metal products that are heavy and difficult or impossible to carry, how about making a sample with a 3D printer?

Also, it takes time and money to create samples when proposing new products. However, with a 3D printer, as long as you have the data, you can easily make it and use it for your proposal.

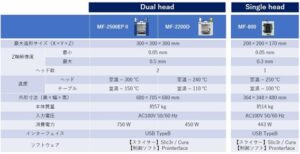

・MF-800

The MF800 is a single head, the other two models, MF-2500EpⅡ and MF-2200D are dual head.

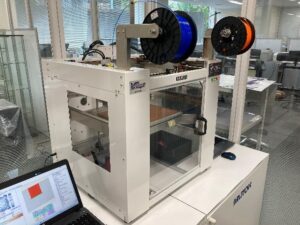

・MF-2200D

A molding table with a heater suppresses shrinkage and warping of the molded object.

A heater has been installed in the molding table to reduce shrinkage and warpage due to temperature changes in the resin. In addition, the drive system has been renewed. The XY axis is a head installed on the top of the housing, and the Z axis is a molding table that moves up and down. As the result, XYZ misalignment is suppressed and high-resolution molding is achieved.

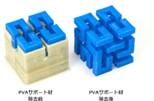

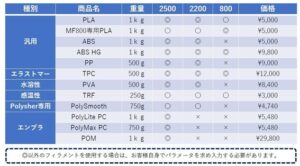

Compatible with various materials

We also support ABS, PLA, and other materials. In the MF-2200D’s feature of different material molding, water-soluble filament PVA can be used as a support material to support the overhang molding. The support material made from PVA can be dissolved in tap water, saving the time of removing the support material.

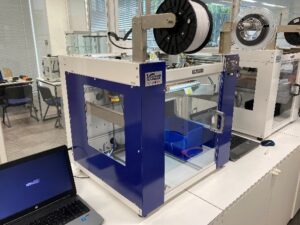

・MF-2500EPⅡ

A new molding table that enables engineering plastic to be fixed

The maximum setting temperature of the molding table has been increased to 150℃. Even engineering plastic can be molded while being fixed to the table. In addition, by incorporating heat insulating material into the bottom of the table and concentrating the heat on the table surface, the table can be heated more efficiently and quickly than conventional models.

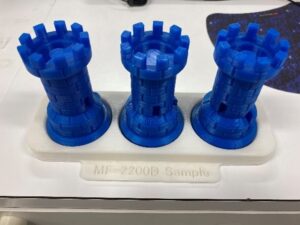

Large model of 300 x 300 x 300mm

With a modeling area of 300 x 300 x 300 mm, which is the largest class for a desktop 3D printer, more dynamic modeling is possible. Equipped with two print heads, it is possible to mold with different materials, such as two-color molding or using one as a dedicated support material. We also have a wide lineup of materials such as PVA resin for support materials.

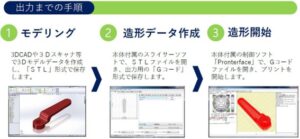

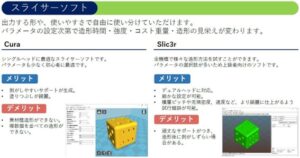

The design drawing of the modeled object, that is, the 3D model data, cannot be read by a 3D printer as it is.

You need to use “slicer software” to translate it into a file for the printer.

Surprisingly, in the MF series, this “slicer software” also supports Japanese!

・Compatible filament materials

・Detailed specifications

・You can also make something like this!

A chair made using the past model, MF-2000.

Even if an employee weighing 80 kg rides, it is fine.

Why not give form to your thoughts and ideas with the MF series?